|

상세 정보 |

|||

| 가공 서비스: | 절단, 펀칭, 디코일링, 벤딩, 드릴링 | 성질: | T3 ~ T8 |

|---|---|---|---|

| 포장: | 체육 가방 판지 | 용인: | ±1% |

| 기준: | 중간 및 고품질 알루미늄 방열판 | 깊은 과정: | CNC 가공 |

| 재료: | 구리, 알루미늄 | 기술: | CNC 및 스카이빙 |

| 강조하다: | CPU 콜드 플레이트 히트 싱크,마이크로프로세서 액체 냉각판,전자 기기 힐 싱크 |

||

제품 설명

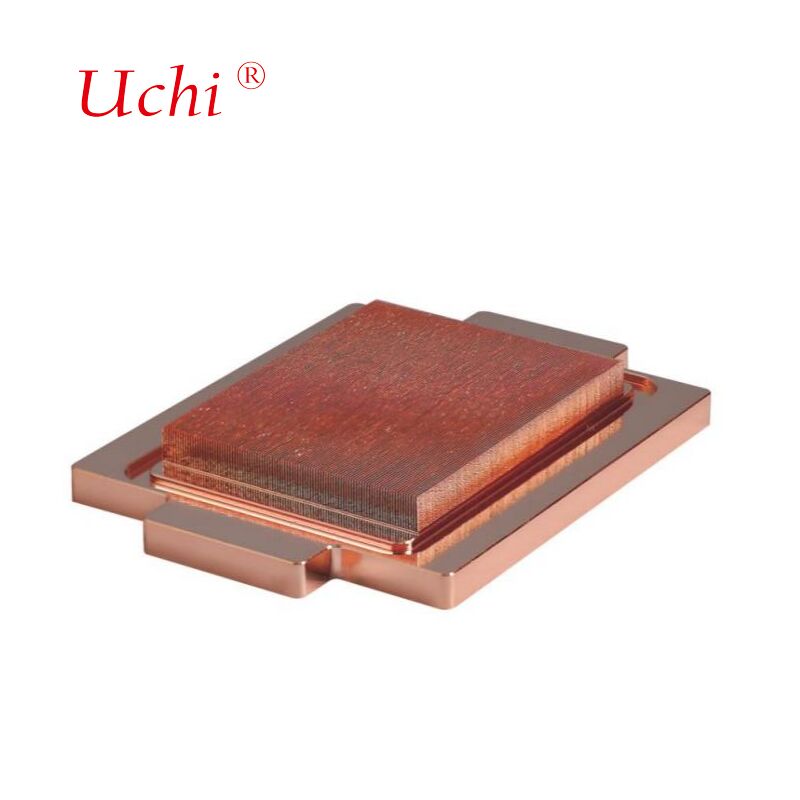

CPU 마이크로프로세서 전자 장치용 냉각판 열기

인공지능, 데이터 센터 및 우수한 열 관리가 필요한 전자 장치를 포함한 고성능 컴퓨팅 애플리케이션을위한 고급 액체 냉각 솔루션.

제조 사양

| 사업 유형 | 공장/제조업체 |

|---|---|

| 제품 | 스키빙 핀 히트리닉, 액체 냉각판, 외출 히트리닉, 스탬핑 히트리닉, 열 파이프 히트리닉, 증기 챔버, CNC 기계 부품 |

| 종류 | 소화기 |

| 서비스 | OEM 서비스, 전문 연구 개발 지원 |

| 소재 | 알루미늄 / 구리 |

| 도구 비용 | 필요 없소 |

| 공정 | 절단, 스키빙, 추출, 스탬핑, 롤링, 브로칭, 펀칭, 드릴링, 굽기, 용접, 프레싱, 턴, CNC 가공, 밀링, 데버링, 청소, 100% 검사, 포장, 배달 |

| 표면 처리 | 닦기, 소금화, 가루 코팅, 비활성화, 페인팅, 플래팅, 샌드 블래스팅, 전자 코팅 등 요청에 따라 |

| 차원 | 맞춤형 (최대 스키비드 히트 싱크 크기: W 1200 × L 3500mm) |

| 검사 | CMM, 2차원 측정기, 프로젝터, 평면 측정기, 거칠성 측정기, 헬륨 누출 테스트 장비 |

| 배달 시간 | 표본 납품 시간: 15~21일 생산 납품 시간: 25일 |

산업용

태양광, 풍력, 통신, LED, 전기차, 의료, 철도 교통, 마이크로파, 자동차, 레이저, 고전력 태양광 인버터, 고전력 LED 조명, 데이터 센터, IGBT 냉각,용접기인공지능

차세대 프로세서용 첨단 냉각 솔루션

인공지능과 HPC가 대용량의 데이터를 처리하는 데 있어서 차세대 프로세서는 현재의 고급 모델보다 훨씬 더 많은 열을 발생시킬 것입니다.BY 테르멀의 액체 냉각 솔루션은 열 분산 효율을 극대화합니다., PUE 값을 개선하고 랙당 컴퓨팅 밀도를 높여 미래 데이터 센터 인프라에 필수적인 액체 냉각을 배치합니다.

고급 제조 응용 프로그램

반도체 및 칩 제조:3D 스파킹과 같은 첨단 포장 기술은 전통적인 재료의 열전도성이 병목이 되는 내부 열 축적을 만듭니다.

인공지능 컴퓨팅/데이터 센터:급증하는 칩 열 흐름 밀도는 전통적인 냉각 방법에 도전하여 열 관리를 컴퓨팅 전력 향상에 중요한 요소로 만듭니다.

항공우주:극한 온도 환경과 진공 조건은 전류 열 분산 옵션을 제거하여 전문 열 관리 솔루션을 요구합니다.

일상적 사용

디지털 장치:컴퓨터, 휴대전화, 게임 콘솔의 금속 냉각지느러미는 지속적인 성능을 보장합니다.

통신장치:큰 히트 싱크는 고속 데이터 전송과 처리에 안정성을 유지합니다.

가전제품:압축기와 응축기는 실내에서 외부 환경으로 효율적인 열 전달이 필요합니다.

조명장치:효율적인 열 분산은 LED 빛의 효율과 연장 수명을 보장합니다.

새로운 에너지 차량:고도화된 액체 냉각 시스템은 최적의 작동 온도를 유지합니다.

제조 능력

우리의 폼 워크샵에는 2개의 MAKINO 거울 EDM 기계, 9개의 와이어 컷 EDM 기계 (일본에서 세이부 3개와 소딕 1개), 7개의 스파크 침식 기계,10 밀링 기계, 2개의 프레싱 머신, 그리고 1개의 톱니.

기술 사양

- 테이블 크기: 500×350mm

- 고속 경로 속도: 5000 mm/min

- 최대 작업 조각 무게: 500 kg

- 최대 전극 무게: 50kg

정밀 공학

SuperSpark4 및 IES (지능 전문가 시스템) 기술을 활용하여 적응력 전원 공급 및 점프 제어로 EDM 프로세스를 안정화하고 가공 정밀도를 향상시킵니다.첨단 초상면 및 초변 발전기 기술은 탁월한 표면 완공과 금속 품질을 제공합니다..

제품 응용

품질 보장

엄격한 품질 표준을 철저한 테스트 장비로 유지합니다.

- 1 좌표 측정 기계

- 1개의 프로젝터 기기

- 2개의 고압 물 시험 기계

- 4개의 열 저항 테스트 기계

- 2개의 액체 누출 테스트 기계

고객 서비스 의 약속

- 모든 문의에 신속한 응답

- 보장된 품질과 경쟁력 있는 가격

- 효율적인 생산 계획

- 최적의 운송 솔루션

- 전면적인 기술 지원

자주 묻는 질문

당신은 무역 회사나 제조업체인가요?

우리는 광범위한 경험과 강력한 기술 팀과 함께 자동화 및 기계화 된 생산을 특징으로 하는 열 싱크 및 물 냉각판의 전문 제조업체입니다.

이전에도 어떤 지역으로 상품을 수출했나요?

우리의 전체 생산량의 60%는 일본, 인도, 영국, 캐나다, 미국, 브라질에 수출됩니다.

얼마나 많은 직원이 있나요?

매출, 구매, 엔지니어링, QA, 창고, 생산 부서에서 약 100명의 직원이 있습니다.

디자인에 동의하면 샘플을 제공할 수 있나요?

예, 우리는 대량 생산 전에 확인을 위해 샘플을 제공, 필요한 경우 기술 도면.

어떤 포장 방법을 사용하시나요?

일반 카튼과 단단한 직물 또는 목재 카튼으로 맞춤 포장 운송 중에 최적의 보호를 위해.

제품 문제에 대한 기술 지원을 제공합니까?

모든 제품은 출하 전에 철저히 검사됩니다. 모든 문제에 대해 우리는 즉각적인 기술적 해결책을 제공합니다.

이 제품에 대한 자세한 내용을 알고 싶습니다