|

상세 정보 |

|||

| 가공 서비스: | 절단, 펀칭, 디코일링, 벤딩, 드릴링 | 성질: | T3 ~ T8 |

|---|---|---|---|

| 포장: | 체육 가방 판지 | 용인: | ±1% |

| 기준: | 중간 및 고품질 알루미늄 방열판 | 너비: | 고객 요구에 따르면 |

| 재료: | 스테인레스 스틸, 알루미늄, 청동 | 기술: | CNC 및 스카이빙 |

| 두께: | 0.5-2.5mm | 애플리케이션: | 산업용, 도어, 프레이밍, LED 방열판 |

| 등급: | 6000 시리즈 | 팬 삶: | 100000 하스 |

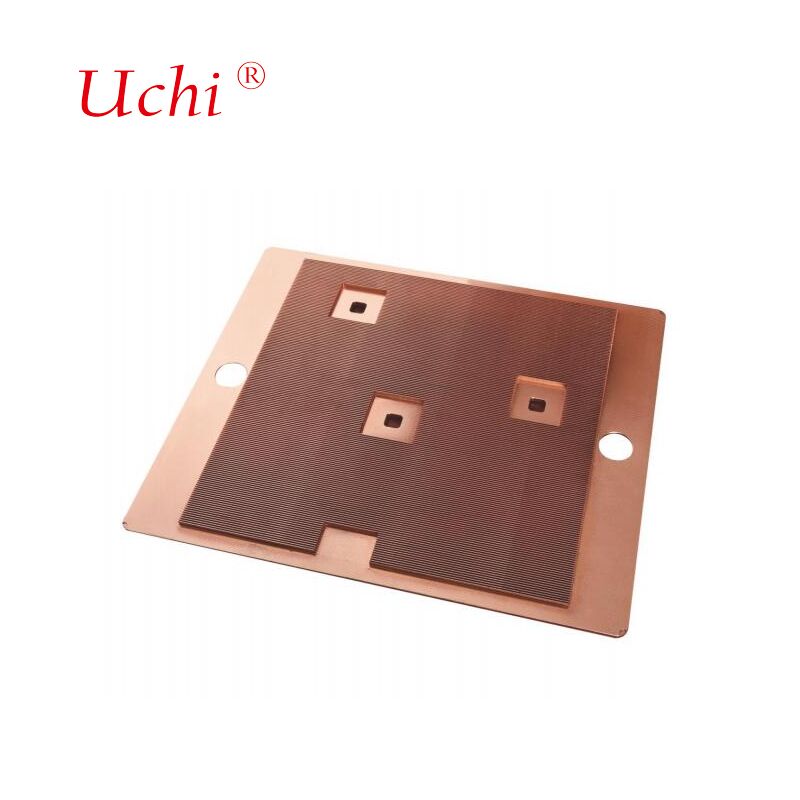

| 강조하다: | 600W 구리 파이프 히트 싱크,벗겨진 핀 히트 싱크,액체 냉각판 히트 싱크 |

||

제품 설명

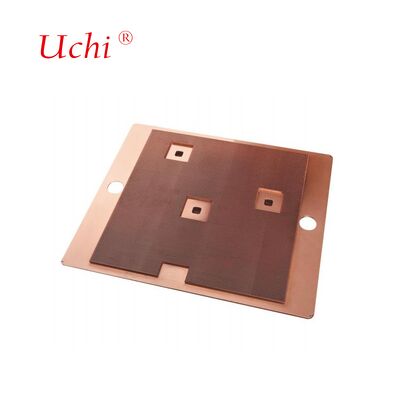

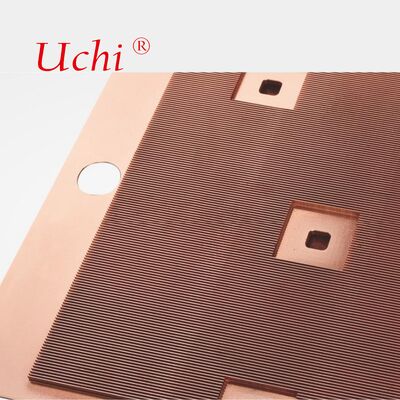

220 시리즈 스키브드 히트 싱크 - 600W 구리 튜브 스키브드 핀 히트 싱크

| 품목 유형 | 맞춤형 히트 싱크 |

|---|---|

| 재료 | 알루미늄, 구리 |

| 크기 | 표준 또는 맞춤형 크기 |

| 색상 | 은색, 검정색, 파란색, 나무색, RAL 분체 도장 색상 등 |

| 모양 | 원형, 사각형, 평면 또는 맞춤형 |

| 두께 | 0.4mm-20mm 또는 맞춤형 |

| 응용 분야 | LED 조명, 인버터, 용접기, 통신 장치, 전원 공급 장치 장비, 전자 산업, 열전 냉각기/발전기, IGBT/UPS 냉각 시스템 등 |

| 생산 공정 | 프로파일 압출 → 절단 → CNC 가공(밀링, 드릴링, 태핑) → 디버링 → 세척 → 검사 → 포장 |

| 마감 | 양극 산화 처리, 밀 마감, 전기 도금, 연마, 샌드 블라스트, 분체 도장, 은 도금, 브러싱, 페인팅, PVDF 등 |

| 심층 공정 | CNC, 드릴링, 밀링, 절단, 스탬핑, 용접, 벤딩, 조립, 맞춤형 알루미늄 제작 |

| 공차 | ±0.01mm |

| 길이 | 맞춤형 길이 |

| MOQ | 낮은 MOQ |

| 포장 | 표준 수출 포장 또는 논의된 대로 |

| OEM & ODM | 사용 가능. 당사 엔지니어는 최적의 솔루션을 위해 귀하의 설계를 검토하고 논의할 수 있습니다. |

| 배송 시간 | 샘플 확인 및 계약금 후 15-20일 또는 협상 |

차세대 기술을 위한 첨단 열 솔루션

AI 및 HPC의 부상으로 대규모 데이터 처리가 필요해짐에 따라 차세대 프로세서는 현재의 고급 프로세서보다 훨씬 더 많은 열을 발생시킬 것입니다. CPU 및 GPU TDP(열 설계 전력)가 계속 증가함에 따라 BY Thermal의 액체 냉각 솔루션은 열 발산 효율을 극대화하고 PUE 값을 개선하며 랙당 컴퓨팅 밀도를 높입니다. 액체 냉각은 데이터 센터의 미래를 형성하는 데 중요한 역할을 할 것입니다.

고급 제조 분야의 응용

반도체 및 칩 제조

3D 스태킹과 같은 첨단 패키징 기술은 칩 내부의 열 축적으로 이어지며, 여기서 기존 재료의 열 전도성은 제한 요소가 되었습니다.

AI 컴퓨팅/데이터 센터

칩 열 플럭스 밀도가 급증함에 따라 기존 냉각 방식으로는 수요를 충족하기 어려워 열 관리가 컴퓨팅 성능 향상의 중요한 요소가 되었습니다.

항공우주

우주 환경은 극심한 온도와 고진공 조건을 특징으로 하며, 대류 열 발산이 불가능하여 항공우주 장비가 혹독한 온도 변동에 노출됩니다.

일상 생활에서의 응용

- 디지털 장치: 컴퓨터, 휴대폰, 게임 콘솔의 금속 냉각 핀이 있는 내부 열 발산 모듈은 지속적인 성능을 보장합니다.

- 통신 장치: 대형 히트 싱크는 고속 데이터 전송 및 처리를 위한 안정성을 보장합니다.

- 가전 제품: 압축기 및 외부 장치 응축기는 실내 공간에서 실외로 열을 전달하기 위해 효율적인 열 발산이 필요합니다.

- 조명 장치: 효율적인 열 발산 설계는 LED 램프 비드 발광 효율 및 긴 수명을 보장합니다.

- 신에너지 자동차: 정교한 액체 냉각 시스템은 최적의 작동 온도를 유지합니다.

회사 제조 장점

첨단 장비 기능

당사의 금형 작업장에는 22세트의 방전 가공기(EDM)가 있으며, 여기에는 2대의 MAKINO 미러 EDM 기계, 9대의 와이어 컷 EDM 기계(일본에서 수입한 3대의 Seibu 및 1대의 Sodick), 7대의 스파크 침식 기계, 10대의 연삭기, 2대의 밀링 머신 및 1대의 선반이 있습니다.

강력한 하드웨어 사양

- 테이블 크기: 500×350 mm

- 급속 이송 속도: 5000 mm/min

- 최대 공작물 무게: 500 kg

- 최대 전극 무게: 50 kg

높은 가공 정밀도

SuperSpark4 및 IES(지능형 전문가 시스템) 기술을 활용하여 가공 정밀도를 향상시키면서 EDM 공정을 안정화하기 위해 첨단 적응형 전원 공급 장치 및 점프 제어를 제공합니다. 당사의 첨단 초표면 및 초에지 생성기 기술은 우수한 표면 마감 및 야금학적 품질을 제공합니다.

제품 응용 분야

품질 보증

다음과 같은 포괄적인 테스트 장비를 통해 엄격한 품질 표준을 유지합니다.

- 1 좌표 측정기

- 1 프로젝터 계측기

- 2 수압 고압 테스트 기계

- 4 열 저항 테스트 기계

- 2 액체 누출 테스트 기계

고객 서비스 약속

- 모든 문의에 대한 즉각적인 응답

- 품질 보증과 함께 경쟁력 있는 가격

- 효율적인 생산 일정

- 최적의 운송 솔루션

- 포괄적인 기술 지원

자주 묻는 질문

귀사는 무역 회사입니까, 아니면 제조업체입니까?

당사는 자동화 및 기계화된 생산을 특징으로 하는 광범위한 경험과 강력한 기술 팀을 갖춘 히트 싱크 및 수냉판 전문 제조업체입니다.

이전에 상품을 수출한 적이 있으며, 어떤 지역으로 수출했습니까?

총 생산량의 60%가 일본, 인도, 영국, 캐나다, 미국 및 브라질로 수출됩니다.

직원 수는 몇 명입니까?

영업, 구매, 엔지니어링, QA, 창고 및 생산 부서에 약 100명의 직원이 있습니다.

설계에 동의하면 샘플을 제공할 수 있습니까?

예, 대량 생산 전에 확인을 위해 샘플을 제공하며 필요한 경우 기술 도면도 함께 제공합니다.

어떤 포장 방법을 사용하십니까?

운송 중 최적의 보호를 위해 일반 상자와 꽉 조이는 천 또는 나무 상자로 맞춤형 포장합니다.

제품 문제에 대한 기술 지원을 제공합니까?

모든 제품은 배송 전에 완전히 검사됩니다. 문제 발생 시 즉각적인 기술 솔루션을 제공합니다.

이 제품에 대한 자세한 내용을 알고 싶습니다